What Do We Mean by QHSE Performance Indicators?

Your performance indicators are unique to your company, particularly depending on your industry. They are usually predefined in advance during the definition of your strategy and the objectives to be achieved.

How important are performance indicators?

Managing QHSE areas in your company can be complex as it requires a rigorous and methodical approach. Performance indicators play a crucial role by providing quantifiable and analyzable data. This allows you to:

1.Assess the effectiveness of current processes: indicators provide objective data to measure the performance of existing processes.

2. Identify areas for improvement: they highlight areas or actions that require special attention to be in a continuous improvement mindset.

3.Ensure regulatory compliance: effective monitoring of indicators helps you maintain compliance with evolving standards and regulations.

4.Improve safety and reduce risks: they help prevent accidents and incidents by identifying potential risks.

What types of indicators should be considered?

The main quality indicators:

Non-compliance rate: measures the percentage of products or services that do not meet established quality standards. These standards are generally defined by current norms or by your management to ensure a certain level of service. A low non-compliance rate indicates high-quality production.

Customer/Supplier return rate: this indicator is directly linked to customer satisfaction. It’s important to consider feedback to identify a potential recurring problem. This rate directly indicates the quality level of your product or service as perceived by your customers.

Response time to customer complaints: by monitoring this indicator, it’s possible to optimize processes and prioritize actions to reduce the time from complaint receipt to resolution. It is important to take the necessary time to respond to and resolve customer complaints, but a shorter response time with good responsiveness reflects the efficiency of your company’s customer service.

The main hygiene and safety indicators:

Frequency and severity of work accidents: these indicators measure the number of accidents per hours worked and their severity, taking into account potential consequences. They are essential to assess the effectiveness of your company’s safety policies.

Absenteeism rate: this rate is not necessarily for issuing sanctions but rather to evaluate the working conditions of your teams. A high rate may imply safety problems within your industry.

Safety audits: audits, in general, provide crucial information for identifying certain points. In this case, it allows you to know your compliance with safety standards and identify areas for improvement.

The main environmental indicators:

Water and energy consumption: these indicators allow you to have visibility on the efficiency of your processes in terms of natural resource consumption and measure your environmental impact.

Reduction of greenhouse gas emissions: these elements are essential for companies with a CSR approach. They are also useful if you want to obtain certain certificates to justify your actions in favor of the environment.

Recycling rate: measures the proportion of waste recycled, which can also be interesting if you have an environmental approach.

How to measure all your QHSE indicators with Daxium-Air?

1. Define your performance indicators.

The first step is to identify the key performance indicators for your company. Depending on your activities, your needs will be different. Therefore, you must define your objectives, to then know the information you need to measure your performance and justify or not the achievement of each objective.

2. Collect your data.

In order to measure the rate of the defined indicators, you need to collect data. Your field teams are then best placed to provide information as they face it daily. Our Daxium-Air application allows you to upload your data from a mobile, thus limiting manual entry errors. Your quality service can quickly provide information about a non-compliant product, including its name, date, product type, detected non-conformity, urgency of processing, and, if necessary, add a photo.

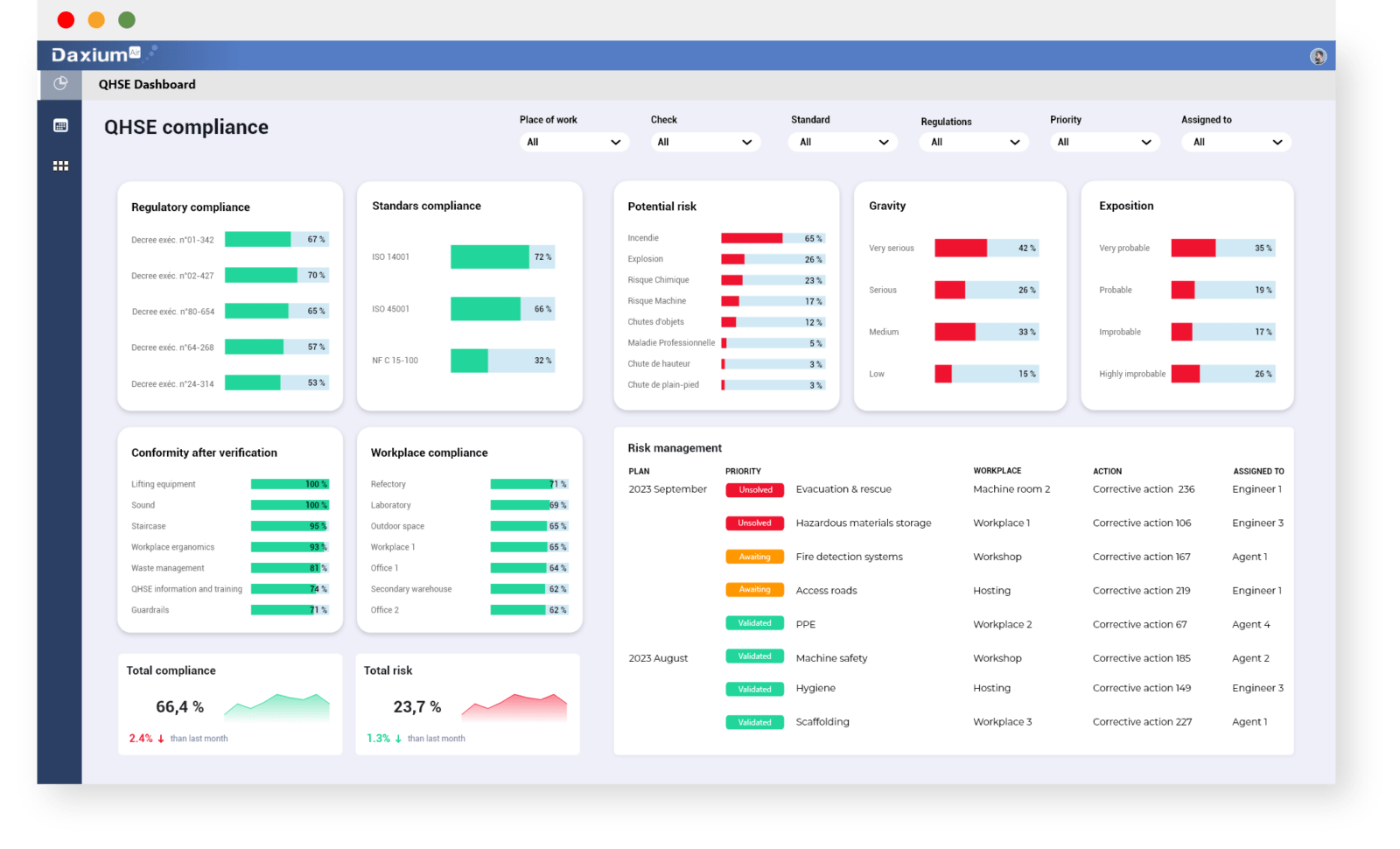

3. Follow your data in real time.

All your collected data constitute your database. Thanks to the real-time monitoring of Daxium-Air, managers or decision-makers have direct access to field information. If an action is declared as urgent, a notification can be sent to the relevant person, enabling you to make quick decisions.

4. Analyze your performance indicators.

You have the option to customize dashboards based on your performance indicators and thus analyze the collected data. You get an overview of your results and can follow your performances in detail.

thanks to your QHSE performance indicators?